Band Saw Blade Sharpening Machine NBS 301

Band Saw Blades Grinders

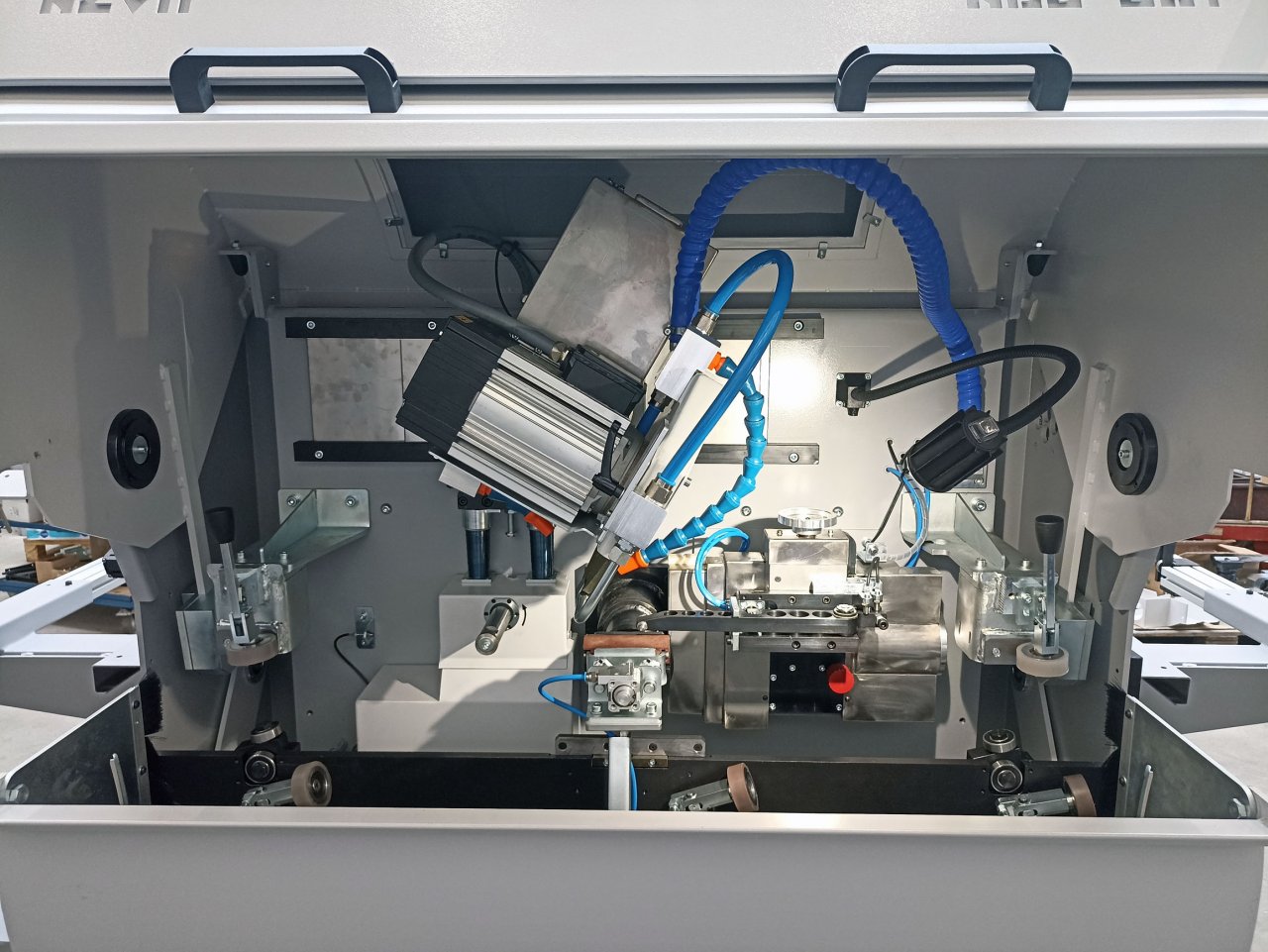

Band Saw Blade Sharpening Machine NBS 301

The next generation of Band Saw Blade Sharpening Machine, the NBS 301 brings the joy of sharpening process – higher quality sharpening results, operator safety and remote access support via internet – backup programs; software updates; via PC or smart phone access to machine display; remote service support; integration into the production process and gathering technological data, etc.

Unlike our other sharpeners, the saw band is oriented vertically during sharpening process. Band Saw Blade Sharpening Machine NBS 301 is equipped by transverse axis and therefore trapezoidal or alternately slanted teeth can be sharpened. Another advantage of the machine is the servo-controlled feeding finger, which ensures a faster cycle run, since it starts to feed as soon as the grinding wheel moves back.

Band Saw Blade Sharpening Machine NBS 301 is ideal for the sharpening of stellite, CV, bimetal and carbide-tipped band saw blades up to 300 mm wide. It operates with ceramic, CBN or diamond grinding wheels using water cooling. Driven diamond dressing wheel with automatic cycle is installed in order to keep the shape of ceramic stone clean and consistent. Thanks to this, the stable and consistent tooth shape of the sharpened blade is ensured.

The grinding cycle is controlled via CNC servo motors; with the result that the saw tooth dynamics remain consistent. Band Saw Blade Sharpening Machine NBS 301 incorporates a coolant reservoir and spray system which helps to keep the saw blades cool during grinding.

Why are our automatic sharpeners unique ?

Advantages at a glance:

- Right and left design

- Simple operation

- Short setup times

- Heavy duty machine design

- Low noise and dirt generation

- Good cost / performance ratio

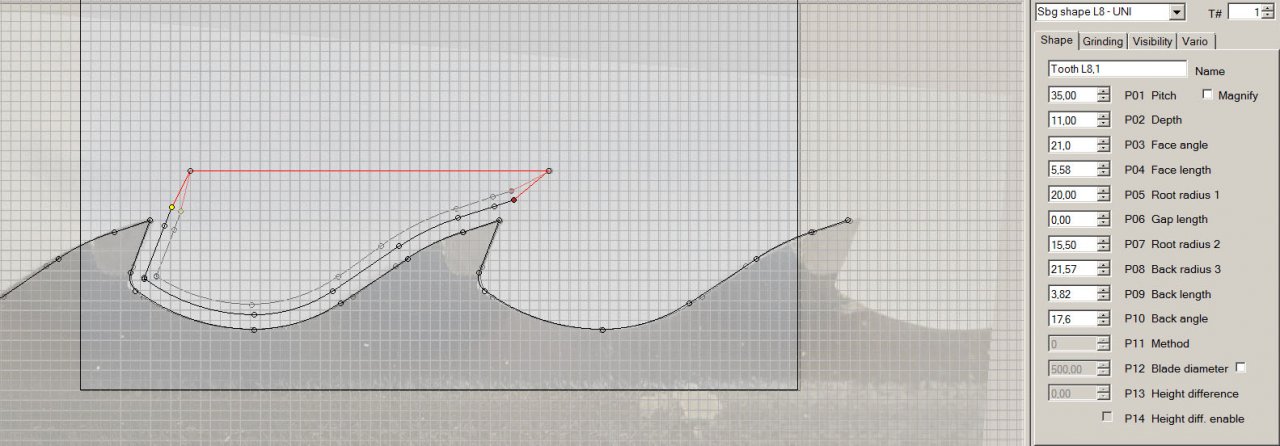

- Opened programming of tooth form including vario profiles

- Coolant tank outside of machine stand including magnetic separator

- A variety of tooth pitches can be ground with the same grinding wheel

- A better finish on the wood is achieved because each tooth is ground more accurately

- More saw blade re-grinds are achieved on the CNC grinder because of its accuracy and consistency. The re-grinds will be consistent from one machine operator to another

- Electronic Hand wheel for even faster and easier adjusting and starting sharpening cycle

- Increased productivity of sharpening due to new patented feeding system

- Machine mechanics behind the working area and separated from the wet sharpening process

- Smoother sharpening results due to integrated spindle with frequency inverter and 300 mm grinding stone

- Equipped by Driven diamond dressing wheel with automatic cycle in order to achieve stable and constant tooth profiles

- Equipped by transverse servo-axis for sharpening trapezoidal and alternately slanted teeth

- Remote access readiness - via RJ45 connection to the LAN and internet network

(overall view at work)

(stellite profiling)

Related products